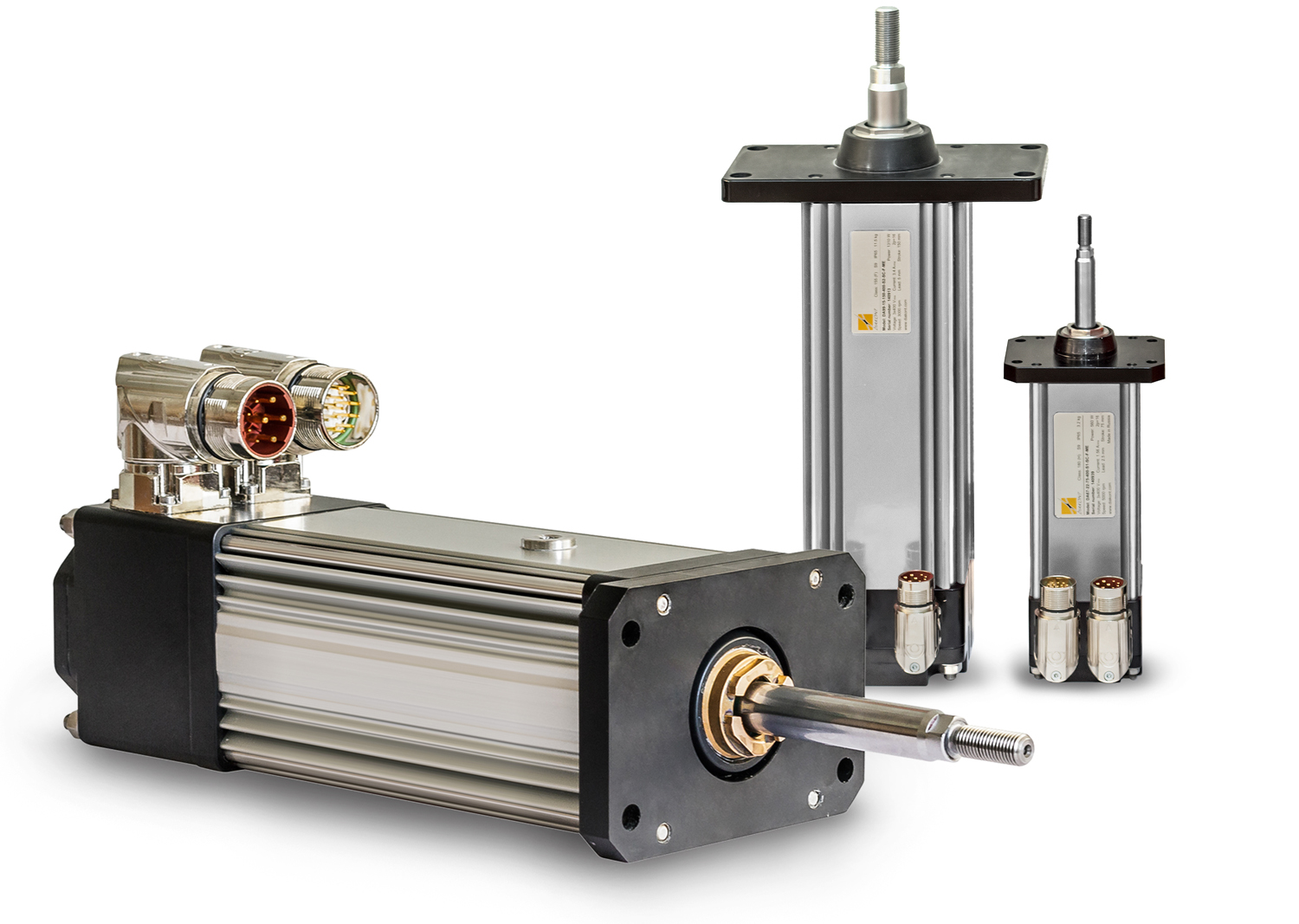

The straight shooters of the actuator world, these convert electrical energy into linear motion. ATEX-certified, these reset to fail-safe positions if the system fails.

Available with a variety of sensors and accessories, our explosion proof actuators are designed for use on quarter turn rotary ‘Max’ valves or Linear ‘Run’ for globe and control valves. Suitable for use in potentially explosive atmospheres, zones 1, 2, 21, 22.

ATEX and IEC Ex db Class 1

In plants where potentially explosive atmospheres are present, safety is an essential concern. For this reason, process safety is guaranteed by using redundant systems. This way, a single failure cannot lead to an unsafe condition. The actuators in the ATEX and IEC Ex db Class 1 series fulfill these requirements perfectly and are therefore ideal for use in safety circuits at the SIL3 level.

The IECEx (International Electrotechnical Commission Explosion-Proof Electrical Equipment) certification system is based on the same standards as ATEX and identifies explosion-proof equipment products with a certificate. This is important, as this provides a guarantee that the product has been built to ensure production safety.

The IECEx system divides hazardous areas into Zones (European method, similar to the IECEX division method) or Classes and Divisions (North American method). These designations indicate which types of equipment can be used in each location and describe the likelihood of an explosive atmosphere. It is also possible to have a product evaluated under both the IECEx and ATEX certification schemes at the same time, since the evaluation criteria are very similar.

ATEX and IEC Ex db Class 2

The ATEX and IECEx systems describe the safety standards and markings for equipment and protective systems intended to be used in potentially explosive atmospheres. These atmospheres can be based on flammable gases, vapors or combustible dusts and are commonly subdivided into Zones which define the likelihood of an explosion occurring, Gas or Dust Groups which determine the explosive properties of the substance and Temperature Classes which determine the auto-ignition temperature.

Both systems align with the IEC 60079 standard. Therefore, products approved for one can easily be accepted in the other, reducing time to market.

The ATEX and IECEx marks are important for equipment designed to be used in hazardous environments. They guarantee that the equipment will work as intended, helping create production safety. Using an ATEX or IECEx certified actuator in hazardous environments can help to reduce operational downtime due to plant shutdowns, making the system more efficient.

ATEX and IEC Ex db Class 3

ATEX and IEC Ex certification indicates that equipment has been rigorously tested and certified to work in environments with potentially explosive atmospheres. These atmospheres are caused by flammable gases, vapors, and combustible dusts. Equipment with ATEX or IEC Ex certification can be used in these areas without the risk of an explosion.

These designations are further subdivided into Zones, Gas Groups, Temperature Classes and Protection Types. The nameplate will display the Notified Body reference, Equipment Group and Equipment Category along with the environment (G for Gas or D for Dust) and the Protection Type or Temperature Class.

Additionally, ATEX requires that a quality audit process be in place to help ensure continued compliance of Ex Certified products. UL can perform these quality audits and is also available to audit facilities that repair existing ATEX Certified equipment. This helps to expedite the repair process and allows your facility to increase market circulation of Ex Certified products.

ATEX and IEC Ex db Class 4

ATEX and IEC Ex certifications are important to consider when designing systems for use in potentially explosive atmospheres. These regulations are designed to ensure that equipment meets minimum safety requirements to reduce the chance of fire, explosions, or other accidents.

Hazardous areas are defined by Zones (European and IECEX method) or Classes and Divisions (North American system) depending on the likelihood of a potentially explosive atmosphere being present. Equipment for use in these zones is marked with an Equipment Category or EPL, gas or dust group and temperature class.

Our Explosion-Proof Valve Actuator is rated to ATEX and IEC Ex db Class 4 making it suitable for all applications in Zones 1 and 2. It is also suitable for use in gases like oxygen, hydrogen, and acetylene in subdivisions C. It can be used in applications such as fire suppression systems, small size ball valves and dampers. Our WE weather-proof and XE explosion-proof actuators are perfect for quarter-turn operating applications in these hazardous environments.