PEEK (poly ether ketone) is a high-performance thermoplastic that is used in medical, automotive, electrical and electronic machinery, and aerospace. It has outstanding comprehensive properties, including high strength, durability and biocompatibility.

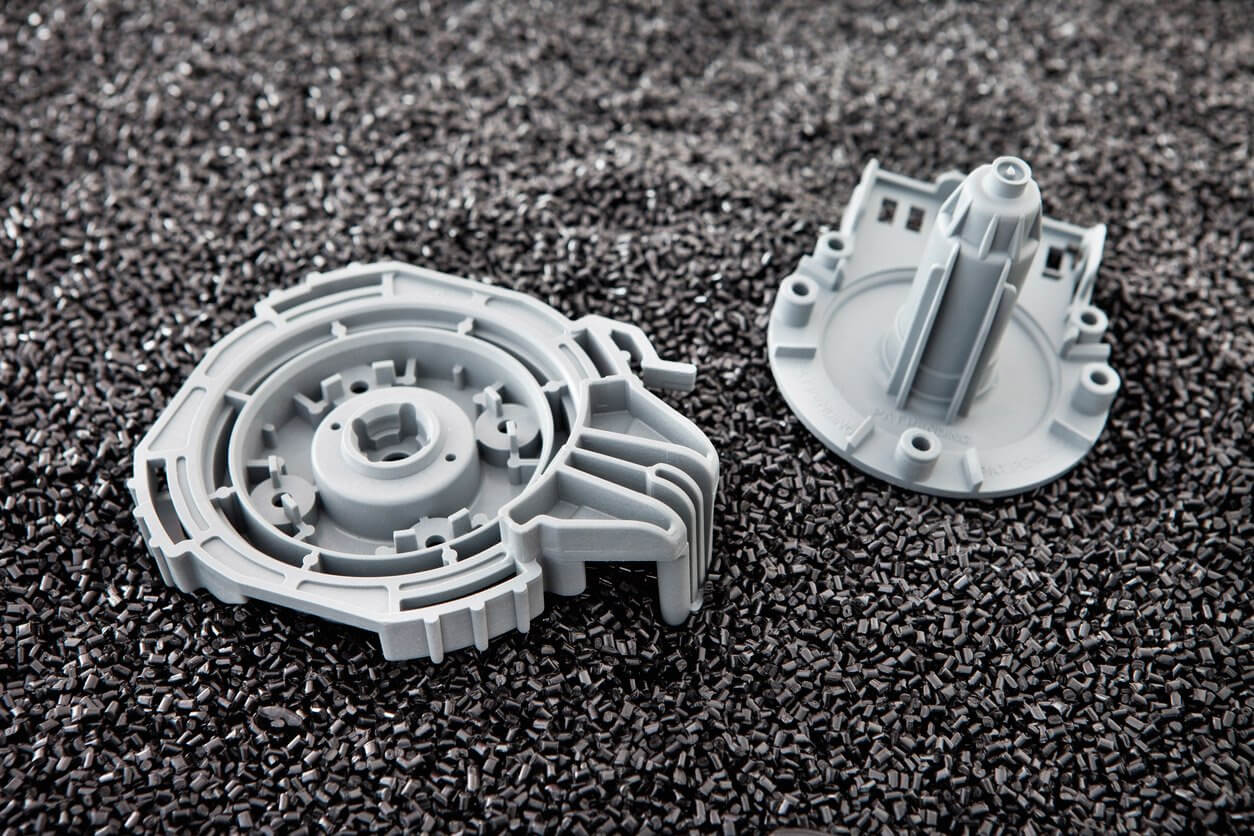

Injection molding PEEK requires extra precautions, like using big gates and clean dry raw materials. The high processing temperature causes residues from other lower melting plastics to degrade and create dark specks on the finished product.

High-Temperature Resistance

Polyether ether ketone, or PEEK, is a semi-crystalline engineering thermoplastic that can withstand high temperatures. PEEK is used in aerospace, automotive and electrical machinery for its superior thermal, mechanical, and chemical properties.

This material also demonstrates good resistance to sterilization processes such as autoclaving, making it ideal for medical applications. It has an excellent electrical insulator and is highly creep-, stress crack, hydrolysis, and wear resistant.

It has a low melting point and glass transition temperature, and its tensile modulus strength is 90-100 MPa. PEEK can withstand gamma radiation and maintain its mechanical properties at elevated temperatures, which is why it is often chosen over metal parts.

Injection molding PEEK requires some extra precautions to ensure a successful run. It should only be used with injection molding machines designed for this material, which have the capability to control the processing temperature and offer large gates for easy flow of the raw material. Barrel blankets should also be used to provide additional insulation and prevent heat transfer to the mold surface.

Biocompatibility

Peek is a specialty plastic with unique properties. Although it is a thermoplastic, it has higher melting and cooling temperatures than other plastics. Injection molding of this material requires careful consideration. Peek is prone to anisotropic shrinkage during the cooling process, which requires special pressure to keep it from deforming or warping. The pressure should be applied based on the direction of the shrinkage.

PEEK injection molding offers high-quality plastic parts for medical and aerospace applications. Its biocompatibility, sterilizability, and strength make it a popular alternative to metals in these applications.

Its ability to tolerate radiation also makes it ideal for medical tools that must be sterilized. Radiation sterilization uses gamma or UV radiation to kill bacteria and viruses. Unlike other plastics, Peek can tolerate these radiations without any changes in its chemical or physical integrity. This means that it can withstand gamma and UV radiation sterilization for medical devices, such as surgical instruments and implants.

Radiation Resistance

Peek molding is more resistant to radiation than other plastics. The polymer undergoes a crosslinking reaction upon exposure to radiation and chain scission in its crystalline state. This makes it gamma and EtO radiation resistant.

The crystalline structure of peek allows it to withstand high-temperature manufacturing and sterilization. This makes it an excellent choice for medical and industrial applications where parts are exposed to a variety of sterilization methods.

When it comes to injection molding, Xcentric has experience working with a wide range of materials, including peek. We can help you find the right material to meet your application needs and bring complex designs to market quickly. We can also help you create a design guide for your project that promotes manufacturability and reduces defects. Request a design cube to learn more.

Strength

PEEK is a strong, durable polymer that can be molded into parts with complex shapes. It has high impact resistance and can withstand a wide range of chemicals, including acids. PEEK can also withstand high temperatures and changes in environmental conditions, making it a good choice for manufacturing parts that need to be sterilized or used in harsh environments.

Peek molding requires special equipment to ensure a smooth process. It’s important to use a machine that’s equipped for high-temperature processing and have adequate space for large gates. This will help prevent silver streaks and cold material defects. It’s also important to use clean, dry raw materials.

A hot oil machine helps to slow down the cooling rate of injection molded parts, which improves their crystallinity. This also reduces internal stresses, which improves tensile strength and impact resistance. It’s also important to design your part according to injection molding guidelines. Following these guidelines promotes manufacturability and controls costs.