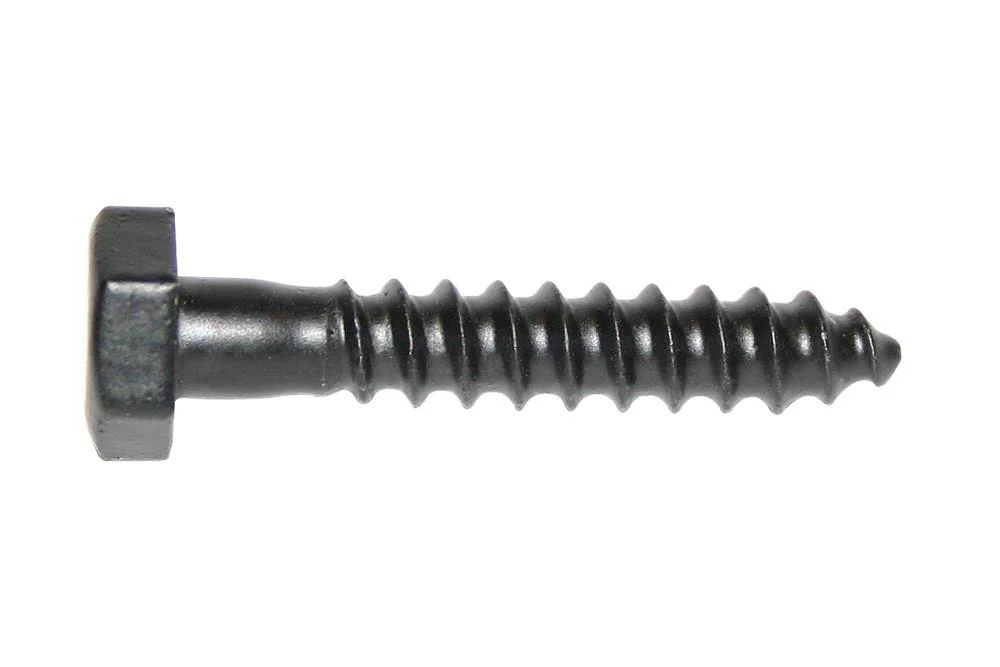

Screws come in a huge variety of sizes and types to suit countless construction tasks. The type of screw you choose depends on the material into which you’re drilling and the size and weight of the load it will support.

When shopping for screws, pay attention to the measurements on their packaging: gauge, length and threads per inch (TPI). Understanding these three dimensions will help you select the right screw for your job.

Length

Many woodworkers find themselves confused when reading plans, instructions or specs that reference specific types and sizes of screws. It is important to understand how this information translates, and the factors that affect screw size.

When selecting a screw, it is generally best to choose one that has a length approximately equal to the thickness of the material it will be used in. A screw that is too short will not anchor properly; a screw that is too long risks extending beyond the material and potentially damaging it.

Screws are typically labeled with two numbers and a nominal length. The first number denotes the screw’s basic diameter, which is also referred to as the gauge; for example, a screw with a number of 2 has a basic diameter of 2. The second number refers to the screw’s thread pitch; this is the distance between adjacent turns of the thread. The ‘nominal length’ refers to the total length of the screw, including the head.

Diameter

Knowing the diameter of a screw can be important to determine whether it will fit through or into your workpiece and into the hole you’re drilling. It can also help you estimate how much thread you have to remove from the hole, if necessary.

The diameter of a screw is measured from the top (crest) of one side to the bottom (root) of the other. For screws with heads, the head diameter is sometimes used instead of the major diameter.

Screw sizes are usually identified by a number with the letter M in the metric system, or an imperial number starting at 1/8″ and increasing by increments of 1/4″. A decimal equivalent of this number is also often given. The first number of the screw size is the gauge, or major diameter; the second number is the thread pitch. Screws with oval heads use a different system for naming, using a number starting at #12 and increasing by adding zeroes.

Pitch

When selecting the right screw for your project, it’s important to consider more than just the length and diameter of the screw. You also need to take into account the pitch and lead of the screw. Pitch refers to the distance between adjacent threads, while lead is the amount of advancement a screw makes after one full revolution.

The vast majority of screw threadforms are single-start threadforms, so their pitch and lead are the same. This means that each time the screw’s body rotates one turn (360deg), it advances axially by the width of one ridge.

When determining the pitch of a screw, you’ll want to use a screw gage. These are similar to a micrometer, but have ridges like teeth that you can hold against your screw to measure the pitch. There are many different types of screw gages, but the most common is called a center gage. These can be purchased at most hardware stores.

Threads per inch

As with length and diameter, thread pitch can be measured using a screw gauge or a caliper. Using a thread pitch gauge will give you an approximate measurement based on already determined thread standards; a caliper will provide a more precise measurement of the distance between the crests of adjacent threads.

Coarse threads have a larger pitch than fine threads; this relates to the size of their axial distance from one thread peak to another, analogous to the difference between coarse and fine grit on sandpaper. This is not to be confused with thread quality, which has nothing to do with tolerances, craftsmanship, or cost.

When choosing a screw, you must be sure to match the appropriate gauge number to your project’s requirements. If you’re unsure, refer to a screw chart or consult an engineer. Also, be sure to check the major diameter, which can be found by referencing the gauge number against a standard, such as a metric screw size chart.3/8 in to mm